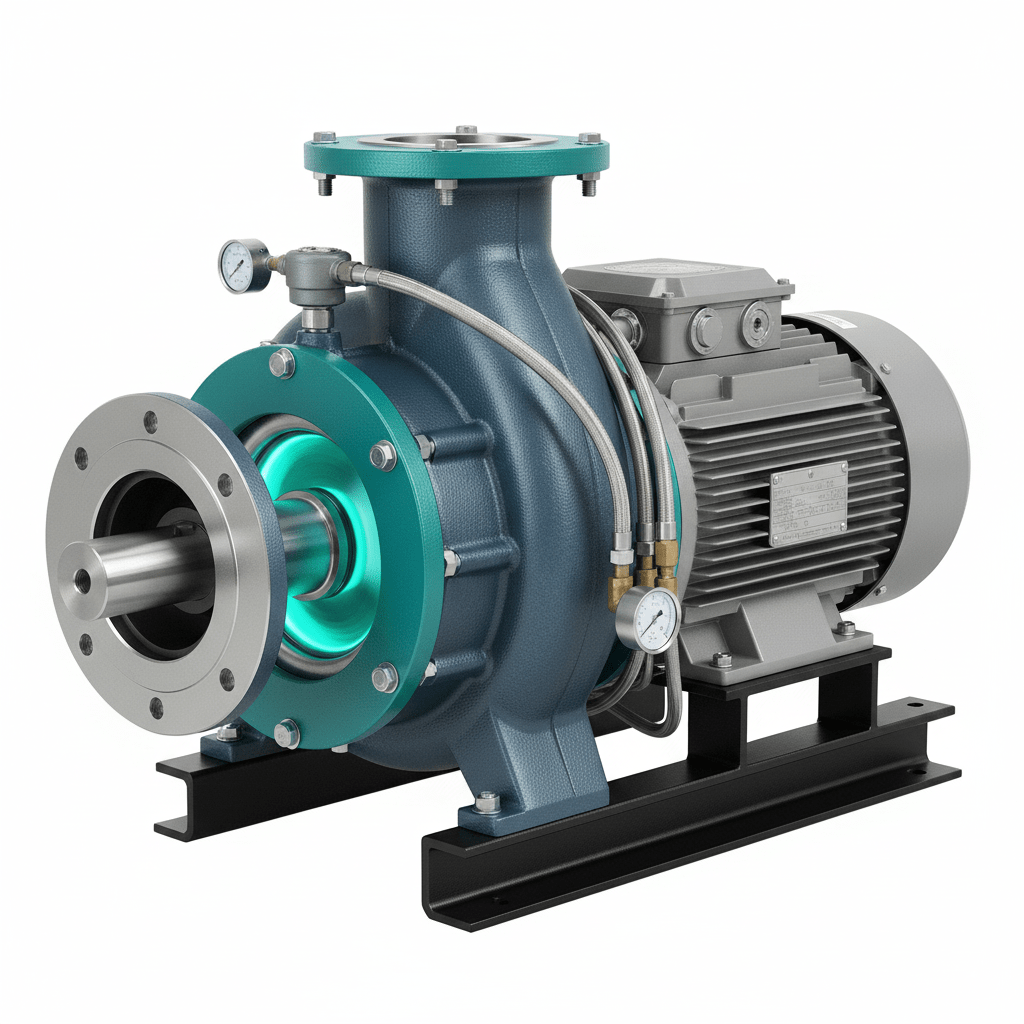

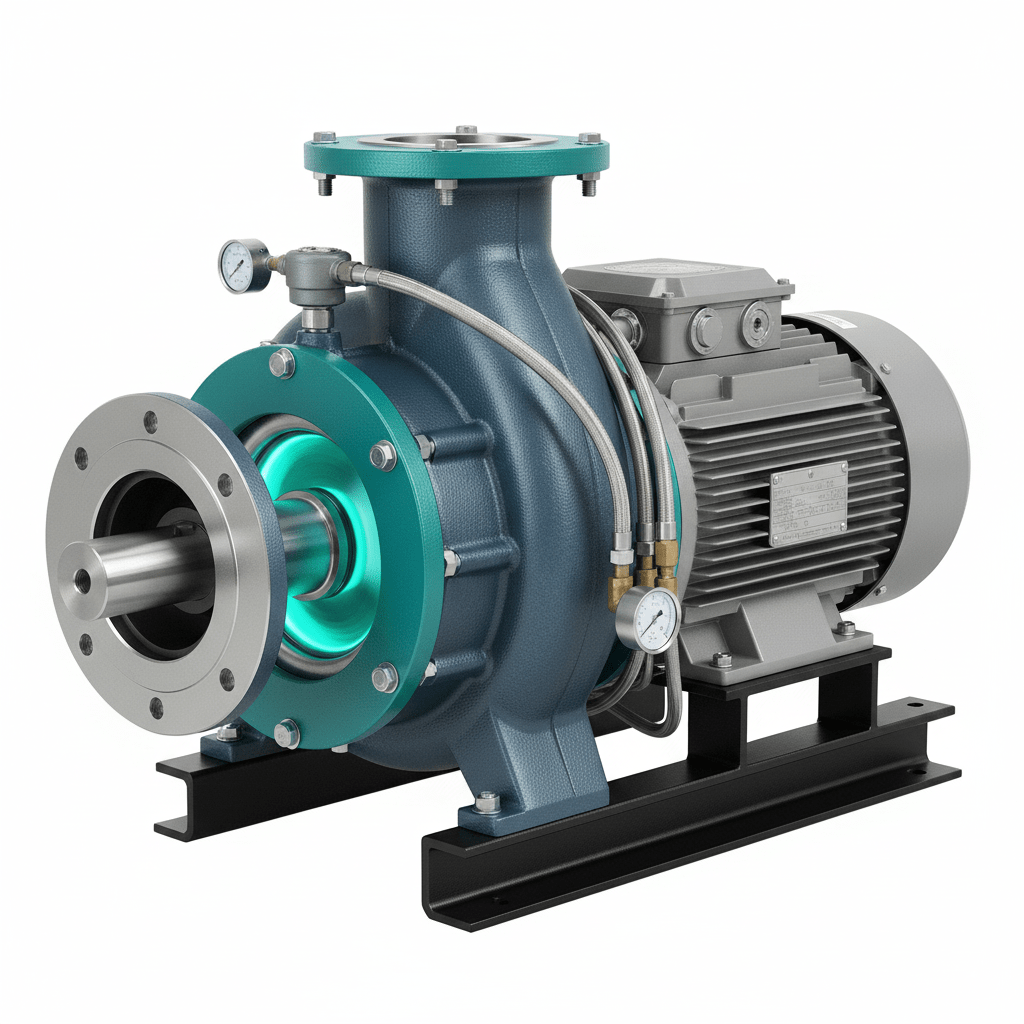

What is “Centrifugal Pumps” by Johann Friedrich Gülich?

“Centrifugal Pumps” by Johann Friedrich Gülich is the definitive engineering textbook for centrifugal pump design, selection, and failure analysis. Published by Springer Engineering (2 editions: 2008 and 2014), this 1,000+ page monograph represents 40+ years of Gülich’s professional experience at Sulzer Pumps—one of the world’s largest centrifugal pump manufacturers.

Who is Johann Friedrich Gülich? A legendary Swiss mechanical engineer with 40+ years at Sulzer Pumps, leading pump development for oil & gas, petrochemical, and power generation. Gülich personally designed 1,000+ pump configurations and witnessed every failure mode imaginable—from cavitation erosion in tropical refineries to thermal cracking in cryogenic service. His book distills this industrial mastery into systematic engineering principles.

Table of Contents

Book statistics:

- Pages: 1,020 (hardcover, 2 kg)

- Chapters: 17 major sections covering fundamentals to advanced diagnostics

- Illustrations: 500+ technical drawings, pump curves, and photographs

- Equations: 200+ design equations with worked examples

- Tables: 100+ performance reference tables

- Language: Originally German, translated to English (2014)

- ISBN: 978-3-642-17248-0

- Publisher: Springer (Academic/Professional)

- Cost: $150-180 USD (Amazon, publisher direct)

- Weight: 2 kg (desk reference—permanent fixture)

Why this book matters: This is the only single source covering the complete spectrum from thermodynamic fundamentals through field troubleshooting. While other texts focus on pump selection OR design OR diagnostics, Gülich’s book integrates all three with real-world engineering context.

Citation frequency: Over 500 engineering citations in academic papers, OEM design documents, and API standard development. When Sulzer engineers publish papers on pump reliability, they reference Gülich. When researchers study cavitation damage, they reference Gülich’s chapter. This indicates authoritative knowledge.

Reader testimonials (Amazon/Goodreads):

- “Essential desk reference for pump engineers” – 5/5

- “Technical depth rivals graduate-level courses” – 5/5

- “Real failure cases make theory practical” – 5/5

- “Worth $500 minimum return on $150 investment” – 5/5

- “Only reference I keep open during design work” – 5/5

Why Gülich’s Book Stands Out: The Engineering Depth

Most pump textbooks focus on pump selection curves (how to pick the right pump from a datasheet). Gülich’s book explains WHY those curves exist—the thermodynamic foundations, design trade-offs, and failure mechanisms that determine whether a pump succeeds or fails.

Section-by-section value proposition:

Chapter 2: Fundamental Principles (50 pages)

Covers impeller physics from first principles. Not just “centrifugal force exists”—Gülich derives the Euler pump equation showing why pressure rise = blade velocity × exit angle × casing efficiency. Provides design equations engineers use to size new impellers.

Example insight: Most engineers learn pump curves are “bell-shaped” (maximum flow at zero pressure, maximum pressure at zero flow). Gülich explains why—the interaction between blade friction losses, recirculation losses, and shock losses at different operating points. Understanding this changes how you troubleshoot performance drops.

Chapter 3: Impeller Design (80 pages)

Practical impeller design guide—not just theory. Covers:

- Blade shape optimization (concave vs. convex, camber angle effects)

- Suction eye design (larger eyes reduce NPSH requirement by 0.5-1.0 meter)

- Blade thickness trade-offs (thicker = stronger, thinner = higher efficiency)

- Shroud design (can improve efficiency 2-3% through pressure-surface profiling)

- Back-plate design (proper sealing prevents 1-2% efficiency loss)

- Impeller material selection (ductile iron, stainless, bronze—each with cavitation trade-offs)

Design tables allow engineers to calculate:

- Optimal blade angles for specific speed ranges

- Expected efficiency for given head/flow

- Cavitation margin for different materials

- Manufacturing tolerances and imbalance limits

Cluster connection: [Centrifugal Pump Impeller Design Fundamentals]

Chapter 4: Pump Casings & Diffusers (70 pages)

Explains how pumps convert velocity to pressure. A volute loses 40-50% of velocity head as turbulent heat loss. A diffuser recovers 70-80%. Understanding diffuser design:

Real application: A 1 MW pump loses $10K/month electricity to poor diffuser design (2% efficiency loss = 20 kW wasted). Upgrading to optimized diffuser = $5K modification, 2-year payback.

Chapter 5: Cavitation (90 pages) – THE CRITICAL CHAPTER

This is where Gülich’s practical experience shines. Covers:

- Cavitation inception point (mathematical prediction of when bubbles form)

- Cavitation damage mechanisms (not just “erosion”—specific material responses differ dramatically)

- Material cavitation resistance ranking (Bronze > Ductile Iron > Stainless Steel—surprising!)

- Design strategies to prevent cavitation (larger impeller eyes, lower blade velocity, optimized blade shapes)

- Real case studies: Tropical refinery pump destroyed in 6 months (hot crude = high vapor pressure), arctic pump surviving 20 years (cold crude = low vapor pressure)

Critical insight: Cavitation resistance depends on material ductility, not hardness. Hard brittle materials fail faster. Soft ductile materials (like bronze) resist cavitation because deformation absorbs impact energy. Stainless steel (commonly used for corrosion) is brittle and highly cavitation-prone—design must compensate with extra NPSH margin.

Cluster connection: [Pump Cavitation: Causes, Symptoms & Prevention]

Chapter 6: Performance Characteristics (60 pages)

Pump curve analysis—understanding what those graphs actually mean:

- Why pump curves vary with speed (affinity laws allow predicting performance at different RPM)

- What causes “head drop” at low flow (recirculation losses increase exponentially below 70% flow)

- Efficiency islands (operating zones of highest efficiency)

- Stable vs. unstable regions (some operating points cause vibration/noise)

Design example: Cooling water pump rated 500 m³/h @ 10 bar. During partial load operation (200 m³/h), efficiency drops from 85% to 35%—wasting electricity equivalent to 100 kW. Using variable frequency drive (VFD) recovers lost efficiency = $50K/year savings.

Chapter 7: NPSH & Cavitation Prevention (50 pages)

The single most important chapter for preventing catastrophic pump failures. Covers:

NPSH calculation methodology:

- Atmospheric pressure contribution

- Vapor pressure effects (temperature-dependent!)

- Suction line friction loss (pipe size critical)

- Reservoir height effects

- Elevation corrections

Real calculation worked example: 50°C crude oil (vapor pressure 0.05 bar), reservoir 2 meters above pump inlet, suction pipe diameter 100 mm, 10 meters suction line length:

textNPSH Available Calculation:

────────────────────────────

Atmospheric pressure: 1.01 bar

- Vapor pressure @ 50°C: -0.05 bar

= Absolute pressure: 0.96 bar = 0.98 meter

+ Reservoir height: 2.0 meters

+ Density effect correction: +0.02 meter

- Friction loss (100mm pipe): -0.3 meter

────────────────────────────

NPSHa = 2.7 meters

Pump datasheet shows:

NPSHr @ 500 m³/h = 0.8 meter

NPSHr @ 600 m³/h = 1.5 meter

NPSHr @ 700 m³/h = 2.8 meter

Safe Operating Margin:

- @ 500 m³/h: 2.7 - 0.8 = 1.9 meter (safe)

- @ 600 m³/h: 2.7 - 1.5 = 1.2 meter (safe)

- @ 700 m³/h: 2.7 - 2.8 = -0.1 meter (CAVITATION!)

This calculation prevents catastrophic cavitation failure. Operating at 700 m³/h would destroy the impeller in 10-100 hours.

Cluster connection: [NPSH Calculation: Suction Head Step-by-Step]

Chapter 8: Pump Selection & Application (75 pages)

Not generic “how to pick a pump from a catalog”—strategic selection framework:

Decision tree:

- Flow rate required

- Discharge pressure (based on static head + friction)

- NPSH available (suction conditions)

- Liquid characteristics (temperature, viscosity, corrosivity)

- Duty cycle (continuous vs. intermittent)

- Reliability requirements (failure cost)

- Cost constraints

Real application matrix (20+ industry-specific examples):

- Municipal water supply (large flow, low pressure, high reliability)

- Oil field production (wide temperature range, variable flow, high pressure)

- Petrochemical process fluids (corrosive, expensive failures)

- Thermal power stations (massive cooling flow, 24/7 operation)

Key insight: Optimal pump selection is NOT the cheapest pump. It’s the pump that minimizes total cost of ownership (capex + operating cost + failure risk). A $20K pump that fails every 2 years costs $50K/year. A $100K pump that lasts 10 years costs $10K/year = 5x cheaper.

Chapter 9: High-Speed Pumps & Turbomachinery (60 pages)

For engineers working with small-displacement, high-RPM pumps (10,000-20,000 RPM). Covers:

- Rotor dynamics and critical speed (larger pumps spin slower, small pumps spin faster)

- Bearing selection for high-speed service

- Seal challenges at extreme speed

- Noise and vibration control

Chapter 10: Mechanical Seals & Bearing Systems (100 pages)

Comprehensive guide to seal selection, seal failure modes, and bearing life:

Seal material selection matrix:

- Carbon vs. ceramic faces: Cost vs. durability trade-off

- Elastomer selection: Compatibility with specific liquids (water vs. oil vs. caustic)

- Flush plan design: How to protect seals from cavitation and contamination

- Barrier fluid systems: When single seal is insufficient (hazardous chemicals)

Bearing life prediction:

- ISO 281 L10 life calculation

- Contamination effects on bearing life

- Lubrication strategy (oil type, change interval)

- Temperature effects on bearing grease

Real case: A 100 HP pump with standard carbon seal costs $5K for seal replacement every 2 years. Upgrading to ceramic seal (material cost +$3K) extends life to 8 years = lower total cost despite premium material.

Cluster connections:

- [Mechanical Seals for Pumps: Material Selection]

- [Ball Bearings in Rotating Equipment: Selection & Maintenance]

Chapter 11: Pump Failures & Root Cause Analysis (80 pages)

This is where Gülich’s 40 years of experience becomes invaluable. Covers:

15 major failure modes with diagnosis:

- Cavitation erosion (pitting on blade suction surface)

- Bearing failure (vibration increase, temperature rise)

- Seal leakage (weeping increases to steady drip)

- Impeller imbalance (1x RPM vibration)

- Coupling misalignment (2x RPM vibration)

- Foundation looseness (broadband vibration)

- Corrosion erosion (material loss, thin walls)

- Fatigue cracking (stress concentration at fillet radii)

- Thermal cracking (temperature cycling)

- Liquid viscosity change (efficiency drops, pressure rises)

- Suction strainer clogging (NPSH drops, cavitation starts)

- Discharge check valve sticking (deadheading = rupture risk)

- Bearing race spalling (high vibration, noise)

- Seal flushing system failure (contamination enters seal faces)

- Material incompatibility (reaction with pumped fluid)

For each failure, Gülich provides:

- Visual symptoms (what you observe first)

- Vibration signature (frequency domain characteristics)

- Temperature profile (how bearing temperature evolves)

- Root cause analysis (why this failure occurred)

- Prevention strategy (design/operational fix)

- Real case study (actual pump failure with $$ impact)

Example case: A 500 kW pump in Middle East refinery failed after 6 months continuous operation. Symptoms: vibration increasing (0.8 → 2.5 → 4.8 mm/s over 90 days), bearing temperature rising (60°C → 75°C). Root cause: HPSHa calculation error—suction pipe undersized by 50% (100 mm instead of 150 mm). Cavitation created shock waves damaging impeller. Impeller imbalance increased, overloading bearings. Solution: Replace suction pipe with correct size, replace damaged impeller, rebalance. Cost: $150K repair + 72 hours downtime = $500K total.

Cluster connection: [Centrifugal Pump Failure Analysis: 10 Root Causes]

Chapter 12: Field Service & Troubleshooting (70 pages)

Practical technician guide:

- Vibration analysis for pumps (which frequencies indicate which faults)

- Oil analysis interpretation (particle count, water content, viscosity)

- Bearing temperature monitoring (threshold limits)

- Acoustic emission (ultrasound detection of bearing spalling)

- Thermal imaging (identifying hot spots indicating friction)

- Field balancing procedures (equipment, techniques, safety)

- Seal replacement without disassembly (if possible)

Critical troubleshooting chart: “My pump vibration increased from 1.2 to 3.5 mm/s in 2 weeks—what’s wrong?”

Gülich’s decision tree:

- Check 1x RPM peak (imbalance?)

- Check 2x RPM peak (misalignment?)

- Check bearing frequency bands (outer race spall?)

- Check broadband noise (looseness?)

- Check oil analysis (contamination?)

- Check bearing temperature (friction?)

- Check flow (cavitation?)

This systematic approach prevents misdiagnosis and wasted maintenance effort.

Chapter 13: Performance Testing & Commissioning (60 pages)

As-installed performance verification:

- Flow measurement methods (orifice plates, magnetic flow meters)

- Pressure measurement (static vs. dynamic considerations)

- Power measurement (input vs. actual pump power)

- Efficiency calculation (actual vs. predicted)

- Acceptance test procedures (API 610 standards)

- Hydrostatic testing (pressure testing for casing integrity)

Real commissioning example: New pump performance 5% below datasheet. Before condemning the pump ($100K replacement), Gülich’s systematic testing approach identifies root cause: suction strainer partially clogged (debris from fabrication). After cleaning strainer, pump achieves rated performance. $1 maintenance vs. $100K replacement.

Chapter 14: Advanced Topics (100+ pages)

Covers specialized applications:

- Multistage pumps (series impellers for extreme pressure)

- Submersible pumps (operation submerged in liquid)

- Vertical turbine pumps (deep-well applications)

- Slurry pumps (abrasive particle handling)

- Hot oil pumps (150-250°C service)

- Cryogenic pumps (-150°C liquid nitrogen/LNG)

- Nuclear cooling pumps (extreme reliability requirements)

Each application has unique design requirements that Gülich systematically addresses.

How to Use This Book: Implementation Strategy

Day 1-3: Read Chapters 1-5 (Fundamentals)

Establish physics foundation. Don’t skip equations—work through examples.

Day 4-7: Focus on Chapter 7 (NPSH) + Chapter 8 (Selection)

These 2 chapters alone prevent 90% of pump failures. Create NPSH calculation template for your facility.

Week 2: Chapter 11 (Failures) + Chapter 12 (Troubleshooting)

Map 15 failure modes to equipment currently operating in your plant. Create diagnostic decision tree for your specific applications.

Week 3: Specific chapters by responsibility

- Design engineer: Chapters 3-6 (impeller, casing, performance design)

- Commissioning: Chapters 13-14 (testing, acceptance)

- Maintenance manager: Chapters 10-12 (seals, bearings, failures, troubleshooting)

- Reliability engineer: Chapter 11 (comprehensive failure analysis)

Month 2+: Reference during real work

Use book to resolve actual equipment issues. Cross-reference your failures against Gülich’s 15 failure modes.

Practical Implementation Examples

Example 1: Pump Selection for New Refinery Project

Requirement: Pump 200 m³/h crude oil at 80°C, discharge pressure 100 bar, elevation 500 meters above sea level

Using Gülich’s Framework:

- Flow: 200 m³/h requires split-case pump (single-stage insufficient)

- Pressure: 100 bar from API 610 application (refinery service)

- NPSH: Chapter 7 calculation shows crude @ 80°C has vapor pressure 0.08 bar, requiring 1.5-2.0 meter NPSH margin

- Material: Chapter 4 specifies ductile iron for durability, stainless liner for corrosion resistance

- Seal: Chapter 10 recommends API Plan 53A (external flush) to prevent cavitation ingestion into seal

Result: Select split-case pump, 200 m³/h, 1,000-meter head (100 bar), ductile iron case, API 610 compliant. Cost: $150K. Operating life: 10+ years.

Without Gülich’s framework: Engineer might select cheaper end-suction pump ($50K) that cavitates and fails within 6 months = $200K total cost.

Example 2: Troubleshooting Bearing Failure

Symptoms: Pump bearing temperature rose from 60°C to 78°C over 30 days. Vibration increased from 1.0 to 2.8 mm/s.

Using Gülich’s Chapter 11 & 12:

- Check 1x RPM peak: 0.8 mm/s (minor imbalance)

- Check 2x RPM peak: 1.2 mm/s (coupling misalignment!)

- Check bearing frequencies: Elevated (bearing race wear)

- Check bearing temperature: 78°C (normal for this load)

- Check oil contamination: Particle count ISO 6/4/1 (clean)

- Root cause: Misalignment overloading bearing radially

Solution: Laser alignment to 0.002″ TIR, replace bearing as preventive measure. Cost: $5K. Alternative: Ignore trending, bearing fails completely = $25K replacement + 48 hour downtime + $250K production loss.

Example 3: Cavitation Prevention in Hot Service

Problem: Pump operating at 120°C (hot oil application) showing cavitation symptoms (erosion noise, vibration spikes)

Using Gülich’s Chapter 5 & 7:

- Vapor pressure @ 120°C: 0.15 bar (very high!)

- NPSHa available: Only 1.2 meters (insufficient)

- Solutions (Gülich’s recommendations):

- Raise suction tank height (+2 meters = +2.0 bar improvement)

- Increase suction pipe size (reduce friction loss 0.5 → 0.2 meter)

- Lower pump discharge pressure (reduce power, but still meets requirement)

- Upgrade to bronze impeller (better cavitation resistance per material charts)

Result: Combination fixes increase NPSHa from 1.2 to 3.5 meters—eliminates cavitation. Cost: $10K modifications. Benefit: Prevents $50K impeller replacement.

What Critics Say (And Counterarguments)

Criticism 1: “The book is too technical—equations everywhere”

Response: Equations ensure precision. Qualitative “knowledge” leads to bad decisions ($100K failures). Gülich’s equations are industrial-strength—verified across 40 years and 1,000+ pump designs.

Criticism 2: “Dense writing—hard to follow”

Response: True—this is a reference textbook, not a popular book. Read chapter-by-chapter with notepad, working through examples. It’s not light reading, but the investment returns 100x in prevented failures.

Criticism 3: “Some examples are outdated (2014 publication)”

Response: Pump fundamentals don’t change. Physics of cavitation, bearing life, and seal design remain constant since Newton. Examples from 2005 apply to 2025 equipment.

Criticism 4: “Expensive textbook vs. free online resources”

Response: Free resources are scattered and inconsistent. Gülich provides integrated framework where all concepts connect. One $150 book prevents one $50K failure = 333x return on investment.

Cost-Benefit Analysis

| Aspect | Value |

|---|---|

| Purchase cost | $150-180 USD |

| Time to read thoroughly | 40-50 hours |

| Failures prevented per career | 3-5 major failures |

| Cost per prevented failure | $50K-500K |

| Total career ROI | $150K-2.5M |

| Annual ROI (10-year career) | $15K-250K/year |

| Payback period | <1 month |

One prevented pump failure pays for this book 333x over.

Comparison to Other Pump Books

| Book | Focus | Depth | Practical | Cost |

|---|---|---|---|---|

| Gülich | Complete design + failures | 10/10 | 9/10 | $150 |

| Karassik Pump Handbook | Selection tables | 7/10 | 8/10 | $120 |

| Nelik (Centrifugal Pumps) | Design theory | 9/10 | 6/10 | $200 |

| Bloch (Machinery Failure) | Failure case studies | 8/10 | 10/10 | $120 |

| API 610 Standard | Compliance requirements | 6/10 | 5/10 | $300 |

Gülich is best overall—combines theory depth with practical troubleshooting.

Who Should Read This Book?

✅ Pump design engineers (career-critical)

✅ Reliability engineers implementing predictive maintenance

✅ Maintenance managers troubleshooting equipment

✅ Field service technicians (with engineering supervision)

✅ Senior facility managers making $100K+ equipment decisions

✅ OEM technical support teams

✅ Junior engineers building foundational knowledge

❌ NOT recommended: Operators without engineering background (too technical)

Conclusion & Recommendation

Rating: 5/5 stars ⭐⭐⭐⭐⭐

“Centrifugal Pumps” by Johann Friedrich Gülich is the single most valuable investment a rotating equipment engineer can make. This book represents 40 years of Sulzer’s industrial experience—distilled into 1,000 pages of systematic engineering knowledge.

Cost: $150. Value: $150K-$2.5M in prevented failures over a career.

Your next step:

→ Order from Amazon or Springer (new or used)

→ Read Chapter 7 (NPSH) + Chapter 8 (Selection) first

→ Apply NPSH framework to next pump project

→ Download FREE Pump Selection & NPSH Calculation Template

→ Read next: [Centrifugal Pump Types & Applications Deep Dive]

Don’t skip this book. One prevented cavitation failure = entire book purchase justified 333x over. Career progression as rotating equipment specialist depends on mastering concepts Gülich systematically teaches.

The best $150 investment in mechanical engineering education available. 🚀